CHLOROPAC Electrochlorination System

- Home

- What we do

- Electrochlorination

- CHLOROPAC Electrochlorination System

Chemical-free, self-cleaning technology used to provide a continuous output of hypochlorite from a feed of sea water

The Chloropac® system processes a sea water side stream from a main sea water flow to continuously produce hypochlorite for reinjection. The Chloropac system produces chlorine, without the need for additional chemicals using a combination of specially coated anode tubes and a direct electrical current. The avoidance of chemicals eliminates the need for storage and handling of liquid hypochlorite, resulting in increased safety and operating cost reduction.

System Overview

More than 40 years of proven application utilizing in-situ self cleaning Chloropac® cells generating sodium hypochlorite.

Chloropac® systems produce, in situ, a dilute, safe solution of sodium hypochlorite for direct injection into the water circuit for prevention of growth of common marine species. Our advanced electrolyzer technology, available in a choice of basic cell designs — coupled with our long standing expertise in anode and system development — has freed thousands of customers worldwide from the cost of purchasing and the danger of handling harsh chemicals associated with other technologies. Evoqua’s Chloropac system is a patented design utilising Concentric Tube Electrolysis cells or CTE technology to provide the most efficient chlorine generation with high internal velocities to keep the cell active surfaces clean. Chloropac system cells are available in a wide capacities, thus enabling the Chloropac cells to be packaged in to standard electrolyser or a full packaged system that are both compact and with significant weight savings. This allows systems to pass through standard hatchways, corridors and into existing footprints with ease. The patented technology is self cleaning so does not require costly acid washing – leaving you to run you platform, vessel or plant, and not worry about biofouling issues.

- Generation is on-site so there is no storage, handling or movement of hazardous chemicals

- IP44 and IP56 (ATEX & IECeX versions) electrical enclosures with easy access and reduced footprint

On-site production

Chloropac® systems produce, in situ, a dilute, safe solution of sodium hypochlorite for direct injection into the water circuit for prevention of growth of common marine species. Our advanced electrolyzer technology, available in a choice of basic cell designs — coupled with our long standing expertise in anode and system development — has freed thousands of customers worldwide from the cost of purchasing and the danger of handling harsh chemicals associated with other technologies. Evoqua’s Chloropac system is a patented design utilising Concentric Tube Electrolysis cells or CTE technology to provide the most efficient chlorine generation with high internal velocities to keep the cell active surfaces clean. Chloropac system cells are available in a wide capacities, thus enabling the Chloropac cells to be packaged in to standard electrolyser or a full packaged system that are both compact and with significant weight savings. This allows systems to pass through standard hatchways, corridors and into existing footprints with ease. The patented technology is self cleaning so does not require costly acid washing – leaving you to run you platform, vessel or plant, and not worry about biofouling issues.

Features

01

Compact, modular design

02

Safe and low maintenance

Simple sealing plastic outer shell and safe access to electrical connections.The MGPS system Is relative compact size, thus making it simple to install.

03

High output availability

Individual Chloropac® system cells easily removed and replaced with minimal downtime

04

Environmentally safe method

No chemical storage or discharge of heavy metals to the aquatic environment

05

Highly configurable

System solutions with the fewest cells possible.

06

Chloropac system cells can be retro-fitted to existing CTE electrolysers

07

Genuie replacement cell parts for older generation Chloropac system cells and Electrocatalytic Systems.

Benefits

01

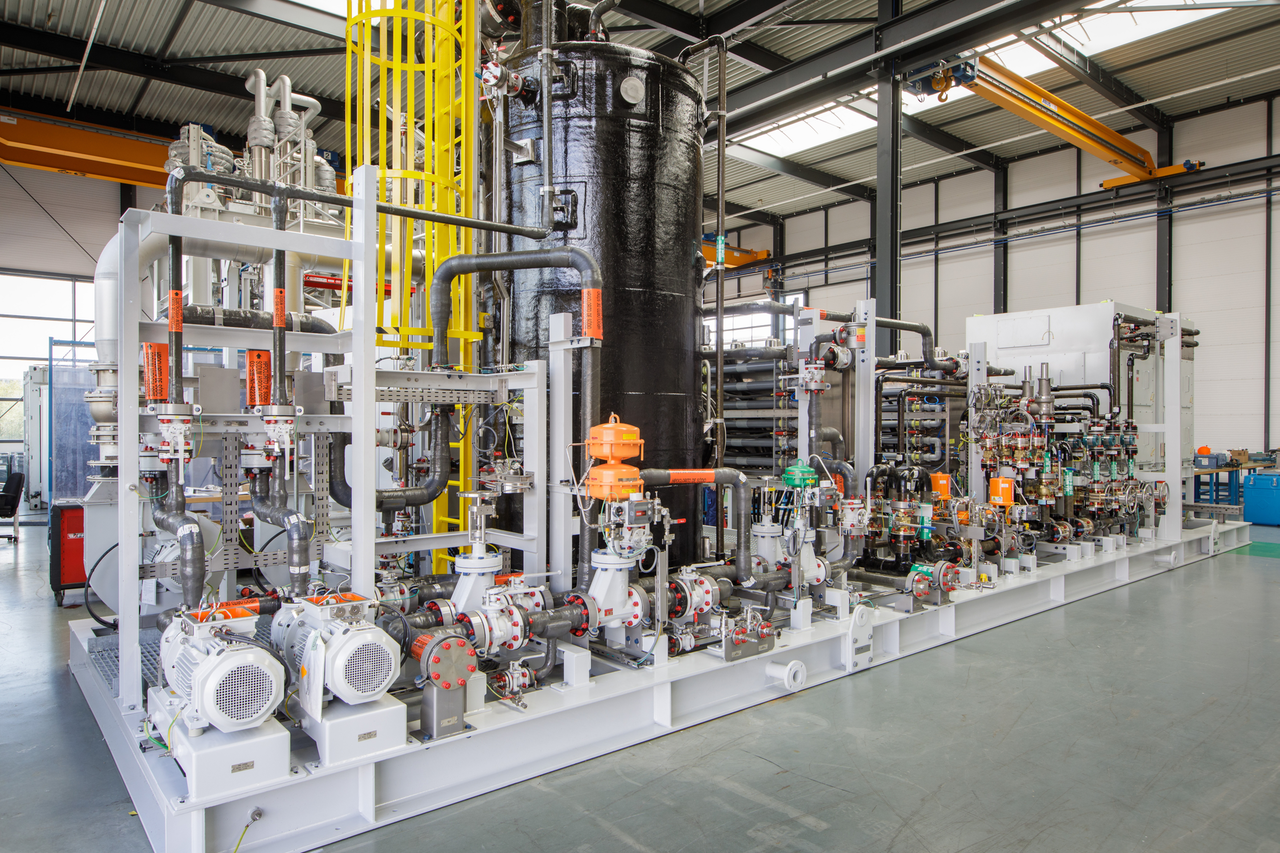

Configured skid mounted packages for easy ingress for offshore and marine applications

02

Larger capacities gained through flexible building block concept

03

Self-cleaning can realize up to 20% cost saving in OPEX over lifetime of your vessel.

Models

MK2M

Electrolyser- CTE Cell

- Self-Cleaning

- No need for acid-cleaning

- IECEx Options

- Multple Connection

MK3

Electrolyser- CTE Cell

- Self-Cleaning

- No need for acid-cleaning

- IECEx Options

- Multple Connection

MK4

Electrolyser- CTE Plate Cell

- Self-Cleaning

- No need for acid-cleaning

- IECEx Options

- Single Connection

Latest

Our Solutions can be certified

We are able to provide options for the certification as follows:

EICS TECHNOLOGY is Evoqua sole agent

for Chloropac systems in Singapore

We are proud to be representing Evoqua Water Technologies – Chloropac System – A leading provider of hypochlorination and electrochemical equipment designed to control biological fouling and corrosion wherever seawater is used as cooling or process water. Have more than 100-year heritage of innovation and industry firsts, market-leading expertise, and unmatched customer service