Electrical earthing or circuit protective conductors (CPC) #

Conductors installed to provide a low impedance path for the current which flows under fault conditions to the general mass of earth. Normally the CPC is connected directly to any associated metal work of the equipment.

Electrical bonding

Conductors installed to establish continuity between adjoining metal work and the armouring of separate cables to ensure that, under fault conditions, all metal work and cable armouring are maintained at the same potential.

Exposed conductive parts include the metal work of switchboards, enclosures, motor frames and transformer tanks.

Extraneous conductive parts are metal work associated with the plant, for example pipe work which can be touched at the same time as a metal switch board cover or motor frame.

System of earthing arrangements #

A system comprises the electrical supply to which an electrical installation is connected.

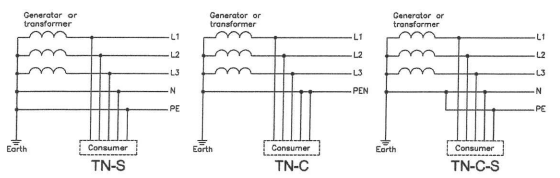

The first letter indicates the supply earthing arrangements where:

- T – direct connection of a point with earth.

- I – no point is connected with earth (Isolated), except perhaps through a high impedance.

The second letter indicates the connection between earth and the electrical device being supplied:

- T – direct connection of a point with earth

- N – direct connection to neutral at the supply origin, which is connected to earth

On the TN system, a third letter added;

- S – separate neutral (N) and protective conductors (PE);

- C – combined neutral and protective earth conductor (PEN)

Type TN earthing system: #

- TN-S: Separate neutral N and Protective conductor PE from transformer or generator to a consuming device. N and PE should not be connected together.

- TN-C: Combined neutral N and Protective conductor PE all the way from transformer or generator to a consuming device.

- TN-C-S: Combined PEN from transformer or generator to building distribution point, but separate PE and N conductors in indoor wiring and flexible cords.

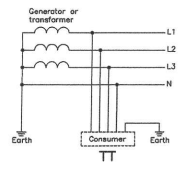

Type TT systems #

- Separate earths for power system and exposed conductive parts.

- Local protective earth connection to earth at consumer.

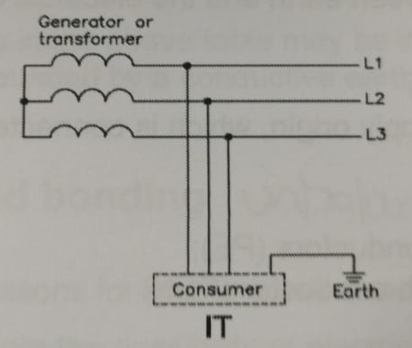

Type IT systems #

- Neutral isolated from earth or earthed through a high impedance.

- The electrical distribution system has no direct connection to earth

- An IR monitoring device must be provided (indicates first earth fault).

Types of earthing system for use in hazardous areas #

- TN-S: Permitted. May be possible to connect to a TN-C system in the safe area.

- TT : Permitted. Protection by residual current device required in Zone 1

May not be acceptable if the earth resistance is high

- IT: Permitted. Insulation monitoring device required.

Supplementary bonding may be required

TN-C and TN-C-S are not permitted in the hazardous area

Potential equalisation #

In order to prevent different voltage potentials occurring in the metal work of plant in hazardous areas, potential equalisation will be necessary. All exposed and extraneous conductive parts are required to be connected to the equipotential bonding system. The bonding system may comprise protective conductors, metal conduits, metal cable sheaths, steel wire armouring and metallic parts of structures, but not neutral conductors. The security of connections must be assured by non-loosening devices.

Earthing conductor cross-sectional area #

BS 7671 gives the minimum CSA of the protective conductor in relation to the CSA of associated phase conductor:

| Phase conductor mm2 | Earth conductor mm2 |

| S ≤ 16 | S, but not less than 4 |

| 16 ≤ S ≤ 35 | 16 |

| S > 35 | S/2 |

The main equipotential bonding conductor must have a cross-sectional area not less than 6mm2, or half that of the CSA of the protective earthing conductor, but need not be greater than 25mm2 copper.

Static electricity #

Static electricity is more than capable of igniting flammable materials and its presence in the petro-chemical industry represents a very high risk which must be countered by the application of appropriate measures.

The passage of oil, gases or dusts through process pipework and containment vessels causes an internal build-up of static charges. This can be minimized or eliminated by ensuring that all pipes, flanges, tanks, etc., are solidly bonded together and bonded to the main earth. Bonding across pipe flanges and joints can also reduce the problem of corrosion caused by static charges.

Lighting Protection #

Earthing and bonding requirements for lighting protection are given in IEC62305, and these include the provision of down conductors every 20m of perimeter for buildings up to 20m height, and every 10m for taller structure.

Conductors for lighting protection must be at least 50mm2 copper or galvanised steel, and the resistance to earth any metal part of the structure should not exceed 10ohms. At least two embedded earthing electrodes should be incorporated.