IEC 60079-14 specifies the cable requirements for fixed equipment in Zone 1 & 2.

Cables sheathed with thermoplastic, thermosetting or elastomeric (“rubber-like”) material may be used in fixed wiring installations. Generally, they should be circular and effectively filled, with extruded bedding. Any filler must be non-hygroscopic.

Mineral insulated metal sheathed cable is suitable for use in hazardous areas.

Cables are normally armoured, but non-armoured types may be used if mechanically protected.

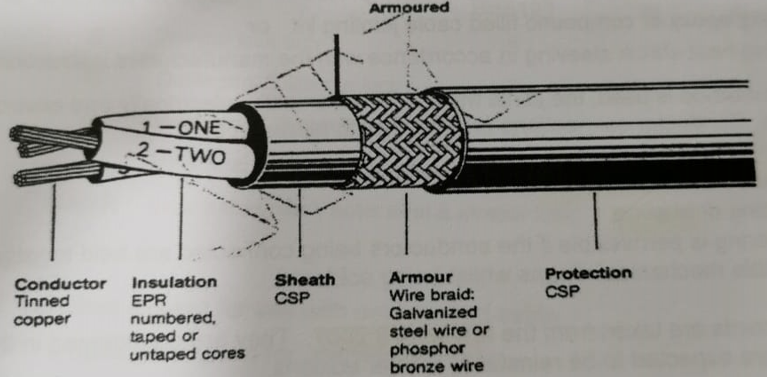

Cables commonly used in the offshore industry are EPR/CSP with braided wire armour, although XLPE/LSF single wire armoured (SWA) types may be found on fixed platforms. PVC or XLPE/SWA/PVC is often used in land installations.

Copper conductors may be used for all sizes of cables, but Aluminium conductors must have a cross-sectional area not less than 16mm2, and be connected via suitable terminals.

Examples of the various permitted cable insulation types are given in the table below.

Elastomeric #

| Chlorosulphonated polyethylene | CPS |

| Cross-linked polyethylene | XLPE |

| Ethylene propylene rubber | EPR |

| Ethylene vinyl acetate | EVA |

| Natural rubber | NR |

| Polychloroprene | PCP |

| Silicone rubber | SR |

Thermoplastic #

| Polyethylene | PE |

| Polypropylene | PP |

| Polyvinyl chloride | PVC |

Cables in Zone 0 #

These would usually be screened cables connected to intrinsically safe ‘ia’ equipment and must withstand a 500Vac or 750Vdc test between conductor to earth, conductor to screen, and screen to earth. Minimum conductor or conductor strand size is 0.1mm2.

Elastomeric Cables #

A typical elastomeric cable comprises EPR insulated copper conductors and CSP inner and outer sheaths (which are heat and oil resistant and flame retardant (HOFR). Operating temperature range is 30°C – 90°C.

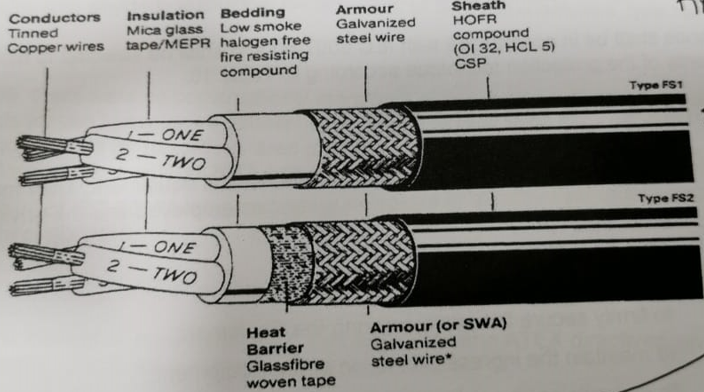

A fire resistant LSF cable is illustrated below:

Insulation colour #

The internationally agreed L.V. colour code is now:

- Phases: brown, black, grey (3 x brown may be used in some circumstances)

- Neutral: blue

- Protective earth conductor: green/yellow

Cables, particularly offshore types, may be encountered with other colour codes.

Where cables of different colour codes are joined or connected together, they must be properly marked to avoid confusion.