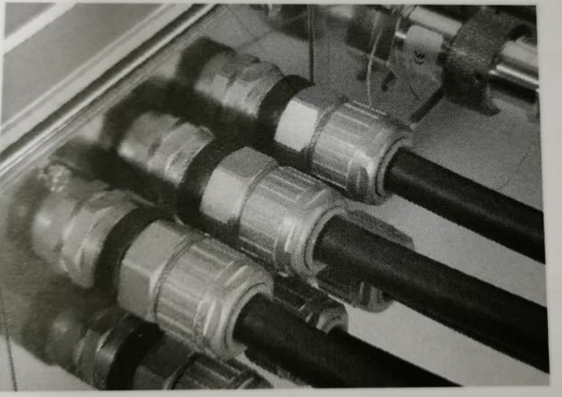

Electrical equipment in hazardous areas may be weird using cable having metallic or non-metallic sheath, or weird in conduit. Today, cable is generally used, mainly because of the ease of installation compared to conduit.

One of the main disadvantages of conduit is the susceptibility to corrosion, particularly on offshore installations. Deterioration due to corrosion can occur relatively quickly and reduce the strength of the conduit.

If conduit is the method of entry to a flameproof enclosure, corrosion could mean that the conduit is not able to contain an internal explosion in the run between the enclosure and the sealing device.

Corroded conduit may not meet the impact resistance requirements essential for use with increased safety equipment.

Cables for use in hazardous areas are not specifically Ex certified, but are required to be constructed from materials as specified in IEC60079-14 and manufactured to relevant standards so that failure is unlikely, providing that the cable has been correctly installed. Typical standards for the manufacture of cables for marine and offshore platforms are BS 6883 and IEC60092.

Fire resistance and flame retardant properties

Cables are selected for fire resistance and/or flame retardant properties, and two standards are relevant:

| IEC60331 (Fire resistant): | A cable manufactured in compliance with this standard will continue to operate in a fire without disruption of essential circuits and emergency circuits. |

| IEC60332 (Flame retardant): | A cable manufactured in compliance with this standard is self-extinguishing and will not propagate the fire. |

The important factors in the performance of cables in a fire include fire survival, fire retardancy, fire propagation, toxicity and smoke emission. Fire resistance is necessary in cabling for essential safety circuits that are required to operate in a fire for a specified time.

Cables may be manufactured from materials (typically polymer compounds) that produce low smoke and fume emissions during a fire. Cables with this capability are known as low smoke & fume (LSF), low smoke zero halogen (LSZH), or zero halogen low smoke (ZHLS).