Type ‘n’ protection is similar in concept to increased safety type ‘e’ protection, and the design features ensure that, in normal operation, sources of ignition in the form of excessive surface temperatures, arcs or sparks are prevented from occurring either internally or externally.

Since the design requirements are not as strict as those for increased safety type ‘e’, it is possible for the manufacturer to install components which produce hot surfaces, arcs or sparks, providing these components incorporate additional methods of protection. These additional methods are described later in this unit.

The principal design features for type ‘n’ are:

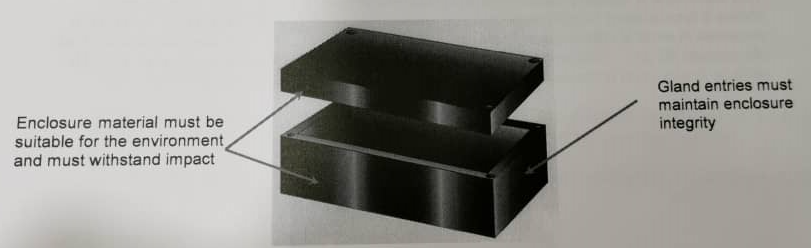

- Enclosures, protective covers, motor fan guards and cable glands are required to be impact tested to standards, accordingly to whether the risk of impact is high or low.

Equipment for low impact areas will have a certificate with suffix ‘X’ - Minimum ingress protection IP54 where an enclosure has exposed live parts internally, or IP44 where insulated live parts are used internally

- Use of certified terminals

- Terminals manufactured from high quality insulation material

- Specified creepage and clearance distances incorporated into the design of the terminals

- Terminal locking devices to ensure conductors remain secure in service.