Additional protection measures #

The additional protection measures included for components which produce arcs/sparks or hot surfaces are explained below:

Energy limited equipment and circuits ‘nL’ #

The previous editions of IEC 60079-15 included the technique of energy limitation, which applied the principles of intrinsic safety to limit the available energy to prevent ignition of a flammable gas.

Energy limiting components are fitted in the Ex ‘n’ equipment itself (self-protected energy-limited equipment) or externally, and typically equipment of this type used zener diodes and series resistors to limit the voltage and current available to sparking contracts and energy storing components within the energy-limited equipment, or at the output terminals of associated energy-limited equipment.

Type ‘nL’ has now been removed from the Ex ‘n’ standard, and is replaced by method of protection Ex ‘ic’, which is covered in unit 7.

Ex ‘nL’ ≡ Ex ‘ic’

Protected sparking devices ‘nC’ #

Sealed device ‘nC’

IEC 60079-15 definition: “A sealed device is a device constructed in such a way that it cannot be opened in normal service and is sealed effectively to prevent the entry of an external atmosphere”. The free internal volume is limited to less than 100 cm3.

Non-incendive component ‘nC’ #

Non-incendive components are components having contacts for making or breaking a specified ignition-capable circuit but in which the contact mechanism is designed and constructed so that the component is not capable of causing ignition of the specified gas atmosphere. The enclosure of the non-incendive component is not intended to exclude the atmosphere or contain an explosion. The technique is usually applied to specially constructed contact mechanisms that quench any arcs or sparks so that they are not a source of ignition. Voltage and current limitations are 254V and 16A, a.c or d.c.

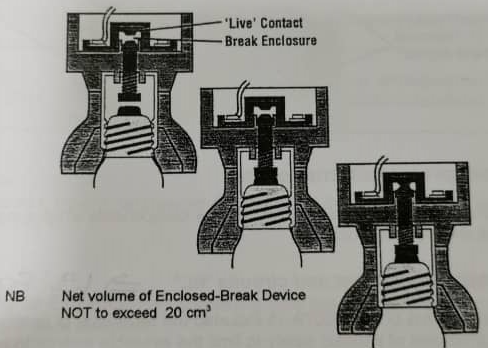

Enclosed break device ‘nC’ #

This technique is typically used in the lamp holders of type ‘n’ equipment. The example shows a typical lamp holder in which there are two sets of contacts. One set of contacts is enclosed in what is effectively a flameproof enclosure in which the free internal volume must not exceed 20cm3. This enclosure is designed to withstand an internal explosion, and the voltage and current limitations are 690V and 16A respectively.

Hermetically sealed device ‘nC’ #

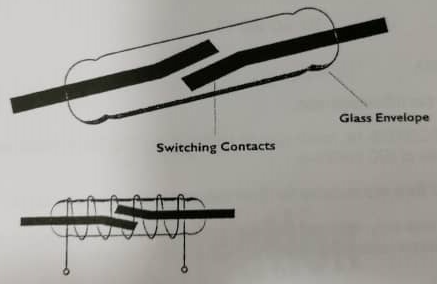

A device which prevents an external gas or vapour gaining access to the interior by sealing of joints by fushion, e.g. welding, soldering, brazing, or the fusion of glass to metal.

The example of hermetic sealing shown below is a reed switch which comprises a set of contacts hermetically sealed within a glass envelope.

Encapsulated device ‘nC’ #

The previous editions of IEC 60079-15 included the technique of encapsulation. The device would be totally sealed by an encapsulating material, typically ‘epoxy resin’, to prevent access of a flammable gas or vapour to an ignition source within.

This technique has now been removed from the Ex ‘n’ standard and is now included in IEC 60079-18 as encapsulation ‘mc’

Encapsulated device Ex ‘nC’ ≡ Ex ‘mc’

Non-sparking equipment ‘nA’ #

An Ex nA device is constructed to minimise the risk of arcs or sparks capable of creating an ignition hazard during normal operation. Examples include Ex nA induction motors.

The requirements for the type of protection Non-sparking, “nA” is covered in increased safety under “ec” in IEC 60079-7: 2015.

Restricted breathing ‘nR’ #

A technique, mainly used in type ‘n’ lighting fittings, in which entry to the interior of the equipment by a flammable gas or vapour is restricted by virtue of good sealing at all joints and cable entries.

Cable entry glands for Ex nR equipment normally utilise a restricted breathing washer, supplied by the equipment manufacturers, in place of normal IP sealing washers.

Ex nR equipment shall be installed in a way that allows easy access to any test port. Equipment should be provided with a test port to enable testing of restricted breathing properties to be carried out after installation and during maintenance, with exemptions for some types of luminaires in the standard.