Introduction #

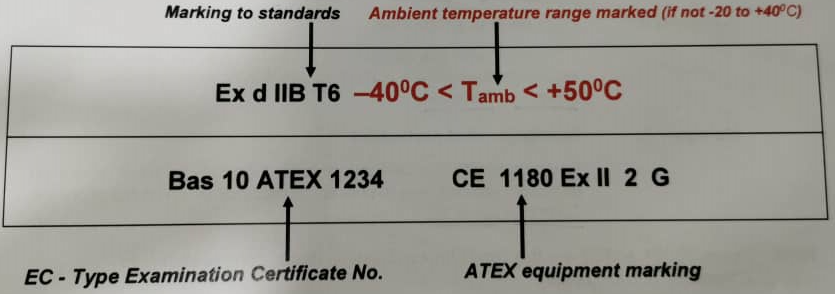

Ex Equipment is marked in accordance with the standards as illustrated below. Equipment complying with ATEX 95 will also be marked in this way, but will have additional markings (see later selection) to indicate that is conforms to the directive.

Equipment certified as providing a method of protection for use in hazardous locations is required to display the following markings:

The symbol Ex, (or EEx if constructed to the EN500—standards)

The type of protection used – ‘d’, ‘e’, ‘n’, etc

The equipment group, IIA, IIB or IIC, and

The T-class, T1, T2 etc

Equipment built to the latest IEC standards will have additional marking to show the equipment protection level (see later section).

Examples:

EEx e II T6 Ex d IIB T3

Further examples:

[EEx ia] IIC Ex d [ia] IIC T5

Ex d IIB+H2 T6 EEx emq II T6

Ex de IIA(NH3) T1

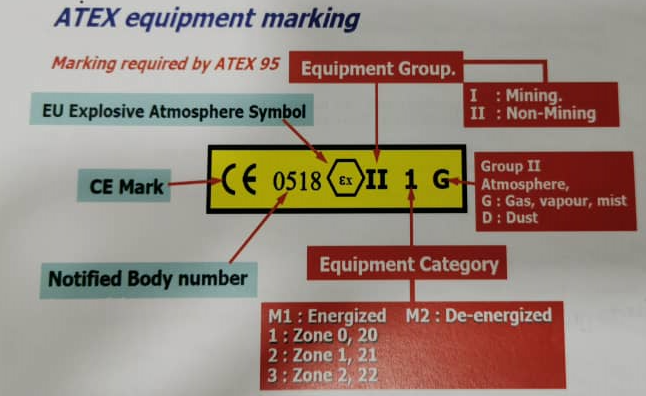

ATEX Equipment Marking #

A detailed discussion of ATEX 95 is beyond the scope of this course. The requirements of the directive for the marking of explosion protected equipment is, however, relevant and is illustrated below. This is in addition to the marking requirements of the constructional standards that the manufacturer may have used to meet the ESR’s of the directive.

ATEX Equipment Label: #

ATEX Equipment Group Definitions: #

ATEX 95 recognises two Group allocations for electrical and mechanical equipment and systems.

Group I for mining industry

Group II for surface industries with explosive gas and/or dust atmospheres.

These compare with the three Group allocations for electrical equipment I the latest editions of the IEC Standards which are:-

Equipment grouping (IEC) #

Group I for the mining industry only – the hazard is firedamp (methane), and/or

combustible dusts. There are no sub-groups.

Group II for surface industries (other than mines) with explosive gas atmospheres.

Subdivided into IIA, IIB and IIC

Group III for surface industries with explosive dust atmospheres. Subdivided by type of

dust into IIIA, IIIB and IIIC

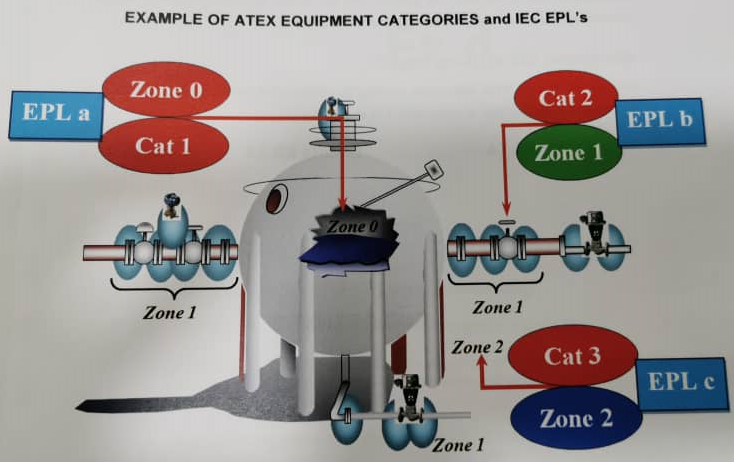

ATEX Category Definitions #

Group I Category M1: Vey high level of protection

Equipment can be operated in the presence of an explosive

atmosphere.

Category M2: High level protection

Equipment to be de-energised in the presence of an explosive atmosphere.

Group II Category 1: Very high level of protection

Equipment with this category of protection may be used

where an explosive atmosphere is present continuously or for long periods, i.e. Zone 0 or Zone 20.

Category 2: High level of protection

Equipment with this category of protection may be used where an explosive atmosphere is likely to occur in normal operation, i.e. Zone 1 or Zone 21.

Category 3: Normal level of protection

Equipment with this category of protection may be used where an explosive atmosphere is unlikely t occur or be short duration, i.e. Zone 2 or Zone 22.

Note: Zone 20, 21 and 22 are the zones for combustible dusts, corresponding to Zone 0, 1 & 2 for gases.

IEC Equipment Protection Levels (EPL’s) #

The latest editions of the IEC 60079 standards have introduced Equipment Protection Levels (EOL’2), corresponding to the ATEX equipment categories.

The EPL’s are: Very High (“a”), High (“b”), and Enhanced (“c”)

This enables a risk assessment approach, taking into consideration the consequences of an explosion, to be implemented for the selection equipment.

EPL Definitions (level of protection) #

Group II gases #

Ga Equipment for explosive gas atmosphere, having a ‘very high’ level of protection, which is not a source of ignition in normal operation, expected faults, or when subject to rare faults.

Gb Equipment for explosive gas atmospheres, having a ‘high’ level of protection, which is not a source of ignition in normal operation, or when subject to faults that may be expected, though not necessarily on a regular basis.

Gc Equipment for explosive gas atmosphere, having an ‘enhanced’ level of protection, which is not a source of ignition in normal operation and which may have some additional protection to ensure that it remains inactive as an ignition source in the case of regular expected occurrences, for example, failure of a lamp.

Group III Dusts #

Da Equipment for explosive dust atmospheres, having a ‘very high’ level of protection, which is not a source of ignition in normal operation, expected faults, or when subject to rare faults.

Db Equipment for explosive dust atmospheres, having a ‘high’ level of protection, which is not a source of ignition in normal operation, or when subject to faults that may be expected, though not necessarily on a regular basis.

Dc Equipment for explosive dust atmospheres, having an ‘enhanced’ level of production, which is not a source of ignition in normal operation and which may have some additional protection to ensure that it remains inactive as an ignition source in the case of regular expected occurrences, for example, failure of a lamp

EPL’s are designated Ma, Mb, Ga, Gb, Gc, Da, Db and Dc

Equipment marked “M” is for use in mines (Group I), that marked “G” is for use in

flammable gases (Group II), and that marked “D” is for use in combustible dusts (Group III).

Risk assessments, Area Classification and Equipment Protection Level/ Categories #

The multi-disciplinary team preparing the area classification drawings will classify the plant into zones, based on the

- Probability

- Frequency and

- Duration

of a release of flammable material.

They can then conduct a series of risk assessments, taking into account the consequences of an explosion at the different locations in the plant, which enables them to choose the EPL/Category of the equipment to be used at these locations.

- Unusually severe consequences of an explosion may dictate the use of equipment with a higher EPL/Category

- Unusually low consequences of an explosion may indicate that equipment with a lower EPL/Category can be used

If these risk assessments have been done, then the EPL/Category required for each location will appear on the area classification drawings, as well as the zoning, gas group and T-Class.

This is an alternative to the traditional method of selecting equipment to suit the zone.

The tables on below show the EPL’s assigned to different types of explosion protected equipment, and the zones where the EPL’s and ATEX Categories may be used, unless the risk assessments dictate the use of another EPL or Category.

IEC equipment levels correspond to ATEX equipment categories, as shown in the tables. #

Gases #

| EPL | Cat. | Protection type | Marking | Zone of use |

| Ga | 1 | Intrinsic Safety Encapsulaton Two separate protection types each meeting EPL Gb | Ex ia Ex ma | 0,1 or 2 |

| Gb | 2 | Flameproof* Increased Safety Intrinsic Safety Encapsulation Oil immersion Pressurisation Powder filled Fieldbus Intrinsic Safety (FISCO) | Ex db * Ex e Ex ib Ex mb Ex o Ex px, Ex py Ex q ** | 1 or 2 |

| Gc | 3 | Intrinsic Safety Encapsulation Non-sparking Restricted breathing Energy limitation Protected sparking equipment Pressurisation Fieldbus non-incendive (FNICO) | Ex ic Ex mc Ex n, Ex nA Ex nR Ex ic (Ex nL) Ex nC Ex pz ** | 2 only |

- 60079-1:2014 introduces ‘da for’ catalytic gas sensors & ‘dc’ for enclosed break devices

All other flameproof equipment is ‘Ex db’ (formerly ‘Ex d’)

** Fieldbus: No designated marking code at the time of writing

Combustible dusts #

| EPL | Cat. | Protection type | Marking | Zone of use |

| Da | 1 | Protection by enclosure Intrinsic Safety Encapsulation | Ex ta Ex ia Ex ma | 20,21 or 22 |

| Db | 2 | Protection by enclosure Intrinsic Safety Encapsulation Pressurisation | Ex tb Ex ib Ex mb Ex p | 21 or 22 |

| Dc | 3 | Protection by enclosure Intrinsic Safety (under consideration) Encapsulation Pressurisation | Ex tc Ex tc Ex mc Ex p | 22 only |

Equipment for mines has EPL ‘Ma’ (with a very high level of protection) for equipment that can be left energised in the presence of an outbreak of gas, and ‘Mb’ (with a high level of protection) for equipment that must be de-energised when gas is detected.