Ducts #

The entry of the inlet duct should be positioned in a non-hazardous location wherever possible

(unless from cylinders). The exhaust duct, ideally, should have its outlet situated in a non-hazardous

location in which there are no sources of ignition, but may be located in a hazardous location if a

spark/particle arrestor is fitted.

Spark particle barriers – requirements accordingly to IEC 60079-14, Table 17

| EPL requirement of location of exhaust duct outlet | Equipment | |

| A | B | |

| Gb | Required* | Required* |

| Gc | Required* | Not required |

A: Equipment which may produce sparks in normal operation

B: Equipment which does not produce sparks in normal operation

*If the temperature of the enclosed equipment constitutes a hazard upon failure of pressurization, a suitable device shall be fitted, to prevent the rapid entry of the surrounding atmosphere in to the pressurised enclosure.

Duct arrangement #

Inlet and outlet ducts passing through hazardous areas are required to be free of leakage so that

flammable gases cannot enter in the event of a fall in protective gas pressure.

Inlet and outlet ducts must be arranged so that they cannot be obstructed causing restriction of the

flow of the protective gas. The ducts should be located where accidental damage is unlikely, and

have adequate mechanical strength and protection against corrosion.

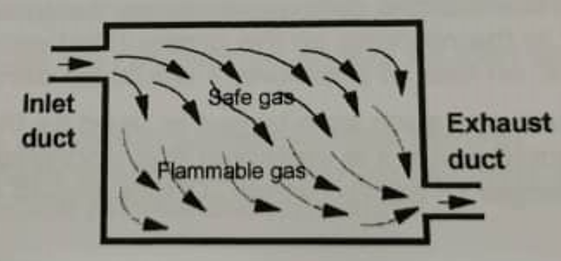

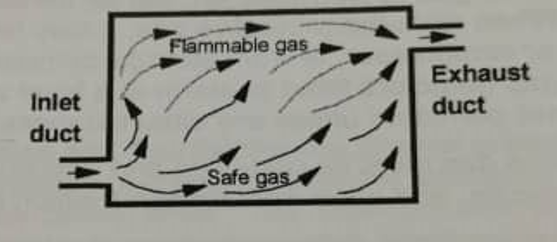

The density of the safe gas relative to the flammable gas has an influence on the position of the inlet

and outlet ducts on the enclosure. This will speed up the rate of displacement of the flammable gas

and so ensure efficient purging of the system.

If the safe gas is heavier than the flammable gas the inlet duct will be positioned at the bottom of

the enclosure and the exhaust duct at the top. If the safe gas is lighter than the flammable gas the

positions of the ducts will be reserved.

- When the safe gas is more dense than the flammable gas:

- When the safe gas is less dense than the flammable gas: