Introduction #

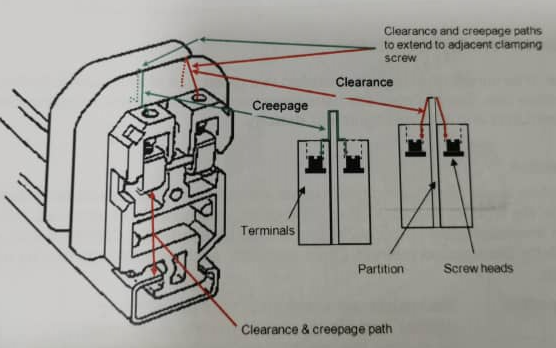

The terminal installed in an increased safety enclosure must be ‘component certified’. They will be manufactured from high quality materials such as Melamine, Polyamide and, for special applications, ceramic. These materials, which have good thermal stability, have been subjected to a ‘Comparative Tracking Index (CTI)’ test t determine their resistance to tracking.

The following definitions apply:-

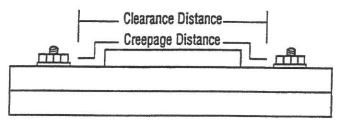

Clearance distance: The shortest distance through air between two conductors. (Flash Distance)

Creepage distance: The shortest distance between two conductors along the surface of an insulator. (Tracking Distance)

Tracking: The leakage current which passes across the contaminated surface of an insulator.

Comparative Tracking Index: Value obtained from a series of tests in which an electrolyte is dripped onto an insulating surface between electrodes having a voltage between them.

Terminal Locking Device #

It is essential that conductors are securely connected in the terminals to prevent sparks occurring as a result of loose connections. The illustration below shows how this is achieved.

Increased safety terminal ratings #

To keep the temperature down, the terminals are de-rated from normal industrial current ratings. This is illustrated by the table for a particular type of terminal, taken from the old BS 5501 Part 6 standard.

| Terminal Type | Conductor Size | Increased Safety Maximum Current (amps) | Industrial Maximum Current (amps) |

| SAK 2.5 | 2.5 | 15 | 27 |

| SAK 4 | 4 | 21 | 36 |

| SAK 6 | 6 | 26 | 47 |

| SAK 10 | 10 | 37 | 65 |

| SAK 16 | 16 | 47 | 87 |

| SAK 35 | 35 | 75 | 145 |

| SAK 70 | 70 | 114 | 220 |

Estimation of Terminal Population #

The number of terminals which can be installed in a given size of enclosure is limited, to limit the temperature rise. Several methods haven been used over the years, including Enclosure Factors, Load Limit and Maximum current density.

Current practice #

For Exe junction boxes constructed to the latest standards the manufacturer’s data will give details of the type, conductor size, current rating, and quality of terminals that may be fitted without invalidating the certification, and should be used. IEC 60079-14 also allows the used of the Watts Dissipation method. Other methods, such as load limit, can be considered to be obsolete.

Watts Dissipation: Enclosures are assigned a ‘Max power rating’ (Watts), and the terminal content is determined by dividing this value by the ‘watts dissipation’ value for the individual Exe terminal.