Flameproof enclosures are supplied complete with all internal components fitted and certified as a single entity by a recognised test authority. The testing procedure will take into account the free internal volume after all the components have been fitted, the temperature rise (determined by the maximum power dissipation), creepage and clearance distances, and the rise in pressure as a result of an internal explosion using a gas/air mixture in its most explosive proportions.

The certification effectively “freezes” the design of the equipment so that any unauthorised modifications will invalidate the approval/certification. Therefore, the following points should be observed.

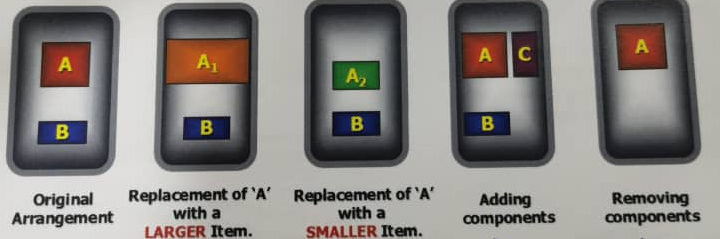

- Replacement of components should always be exactly the same as the original specified components in order to avoid infringement of the certification. A component larger or smaller than the original will affect the internal geometry of the enclosure. Pressure piling is a possibility if a larger component is fitted, and increased volume will result if a smaller component is fitted.

- Adding components is also forbidden because of the possibility of increased explosion pressure as a result of pressure piling.

- The removal of components must also be avoided since an increase in the free internal volume will result. The original test results, prior to certification, would be compromised as a result of a modification such as this.

Some other unauthorised modifications

- Use of wrong size / type of hole sealing plug

- Use of wrong size / type of cable entry gland

- Misuse of constructional screws or bolts

- Attaching cable brackets using cover fixing bolts

- Drilling holes

- Adding / removing gaskets

- Using hardening sealants or tapes

- Changing layout of components

- Adding additional components

- Removing or omitting components