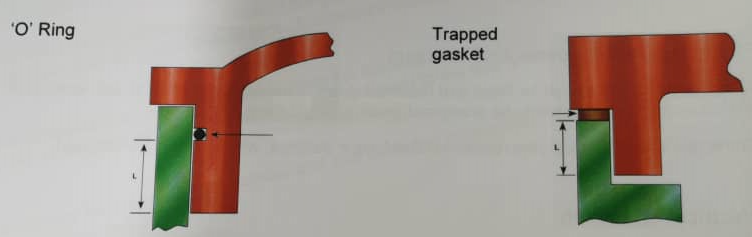

The diagrams illustrate typical locations of gaskets or rubber ‘O’ rings for ensuring a high level of ingress protection.

The gasket etc. must be an integral part of the original design, i.e. they cannot be added at a later date to an enclosure manufactured without gaskets. If they are part of the design, they must be in place and in good condition.

Use of tape #

If environmental conditions are extreme, non-hardening grease-bearing textile tape may be applied outside straight flanged joints, subject to the following limitations of use:

Non-hardening tape maybe applied around the flamepath of equipment with flanged joints of

group IIA equipment, by applying one layer only with a short overlap.

For group IIB equipment, providing the gap is less than 0.1mm, one layer with a short overlap may

be applied around flanged joints.

Tape must not be used on Group IIC (or IIB+H2) equipment.

Use of grease for corrosion protection #

Non-setting grease or agents without evaporating solvents may be used on the machined flamepath joint surfaces for corrosion protection. One such agent is available in the form of a PBC grease specifically approved for flamepath use, and will inhibit the formation of rust on these surfaces. Silicone based greases are also suitable, but require careful consideration in order to avoid possible damage to the elements of gas detectors. Petroleum bases greases can cause rubber (O-rings, gaskets, seals etc) to perish – so beware!

Use of paint #

Whilst the surfaces of the flameproof joint must not be painted, painting (by the user) of the complete assembly is permitted. Some paint will inevitably penetrate into the outermost part of the gap and the use of non-hardening grease will reduce (but no eliminate) the quality penetrating.

All traces of paint must be removed before assembly. Use solvent, fine steel wool etc, NOT scraper or file. Aluminium paint should not be used.

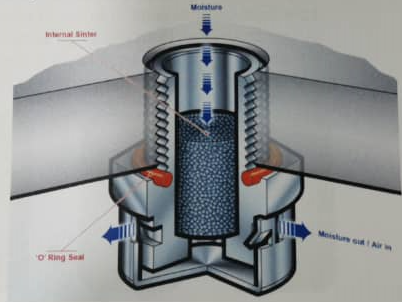

Use of Drain/Breather (Ex d components certified) #

Manufacturers may fit component certified drain/breathers to allow the flameproof enclosure to breath and to drain away any accumulated water inside.

The internal “sinter” or metallic gauze presents a very large surface area to any escaping gasses, and thus functions as a flamepath.